In the previous article, we talked about the advantages of freeze-drying in food. Today we talk about the application examples and advantages of freeze-drying in medicine.

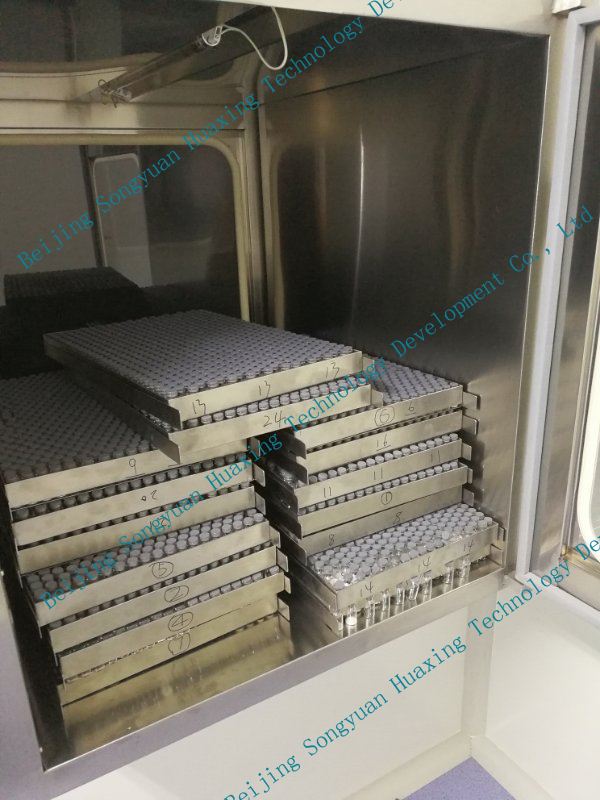

The drug freeze dryer is referred to as a drug freeze dryer, and the drying process can be divided into two stages, one drying and two drying. Free water is removed in one drying stage and a portion of the bound water is removed in the secondary drying stage. The drying process occupies most of the energy consumption of the freeze-drying process of the drug, so it is very meaningful to take effective measures to increase the drying rate. At present, most of the measures to control the temperature of the shelf and the temperature of the drug, the temperature of the cold trap and the degree of vacuum are used to achieve an increase in the drying rate.

1. Control of drug temperature: including temperature control of frozen layer and dried layer. The principle of controlling the temperature of the frozen layer is to ensure that the frozen layer does not melt (below the eutectic point), the higher the temperature, the better. The principle of controlling the dry layer temperature is to use a higher drying temperature as much as possible without denaturation of the material or collapse of the dried layer structure. The shelf temperature control is to meet the drug temperature control standard.

2. Cold trap temperature: The driving force of water sublimation during lyophilization is the temperature difference between the drug and the cold trap. Since the temperature of the drug is limited by the heating mode and cannot be higher than the eutectic temperature, the lower the temperature of the cold trap, the better. In order to improve economy, it should be at least 20 °C lower than the drug temperature during the sublimation drying process; in the desorption drying process, the cold trap temperature of the drug freeze dryer is lower for those formulations requiring very low residual moisture.

3, vacuum: It is generally believed that the pressure has positive and negative effects on the freeze-drying process:

a) Below the eutectic temperature and collapse temperature of the drug, the higher the sublimation interface temperature, the more sublimated water vapor, the greater the heat required. The higher the pressure, the higher the thermal conductivity of the dried layer, and the greater the surface convection. Therefore, the faster the sublimation water vapor, that is, the higher the lyophilization rate.

b) The sublimation interface is related to the difference between the evaporation velocity of the dry layer to the outside and the pressure difference between the interface and the surface, that is, the saturation pressure corresponding to the interface temperature and the vacuum of the drying chamber. This pressure difference is large, which helps the water vapor to escape. The smaller the pressure difference, the slower the escape and the smaller the drying rate. If freeze drying is a heat transfer control process, the drying rate increases as the drying chamber pressure increases; if freeze drying is a mass transfer control process, the drying rate decreases as the drying chamber pressure increases. Experience has shown that the vacuum in the sublimation stage is between 10 and 30 Pa, which is beneficial to the transfer of heat and to the sublimation. If the pressure is too low, the heat transfer is unfavorable, the medicine is not easy to obtain heat, the sublimation rate is lowered, and the requirements for the equipment are higher, which increases the cost. When the pressure is too high, the sublimation speed of the internal ice of the medicine is slowed down, and the heat absorbed by the medicine is reduced, so that the temperature of the medicine itself rises. When the temperature is higher than the eutectic temperature, the medicine will melt and cause the freeze-drying failure. According to the influence of vacuum on the freeze-drying rate, the literature [40] adopted the cyclic pressure method and obtained good results.

The drying process of the drug freeze dryer is a continuous operation, different drug formulations have different freezing characteristics, and the freeze-drying curve is also different. Therefore, individual research should be carried out on the basis of basic research to optimize the freeze-drying curve and improve Drying rate reduces energy consumption.

What are the advantages of such a pharmaceutical freeze dryer?

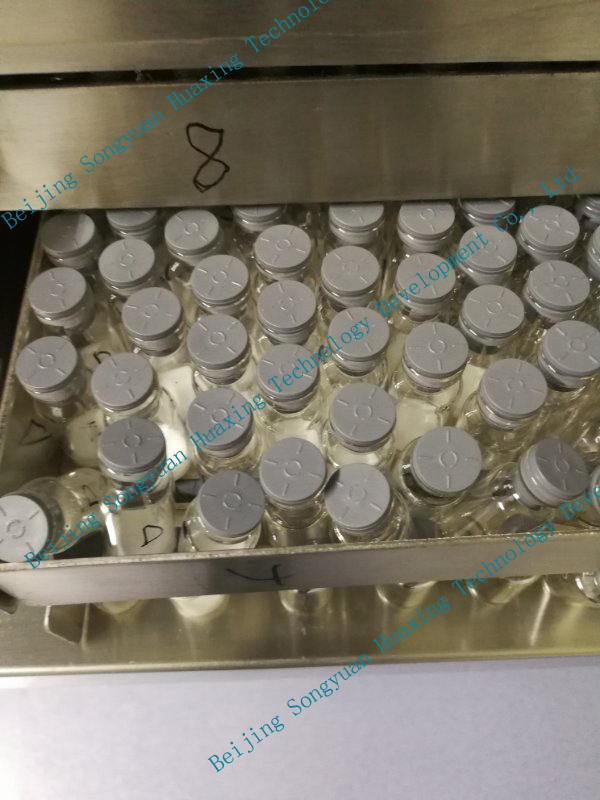

Freeze drying of drugs:

1. The medicine is dispensed before freezing, and the dosage is accurate.

2. Dry at low temperature to retain the heat sensitive substance in the dried drug.

3. Drying under low pressure, the dried drugs are not easy to oxidize and deteriorate, and at the same time can sterilize or inhibit the vitality of certain bacteria due to lack of oxygen.

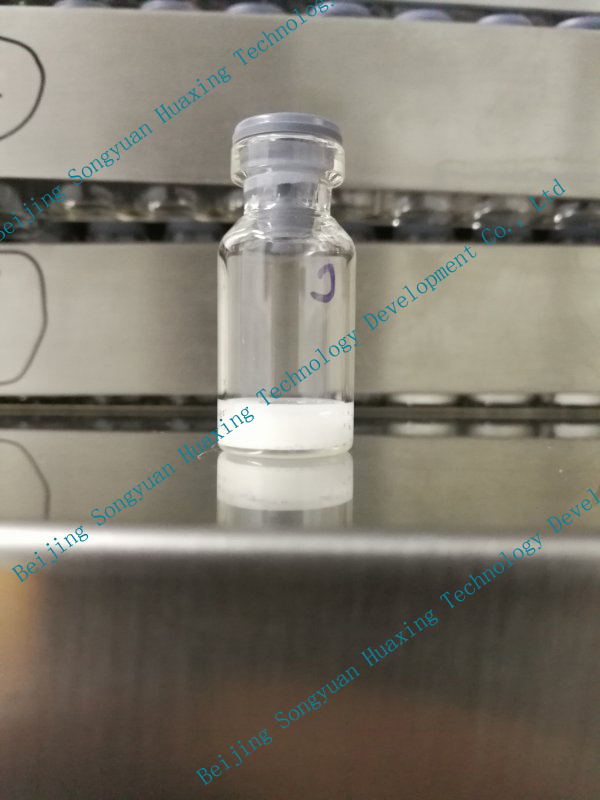

4. The dried drug can form a "skeleton" when frozen, and can maintain its original shape after drying, forming a porous structure and the color is basically unchanged.

5, good rehydration, freeze-dried drugs can quickly absorb water to reduce the state before lyophilization.

6. Dehydrated thoroughly, suitable for long-distance transportation and long-term storage.

+86-13161061539

+86-13161061539