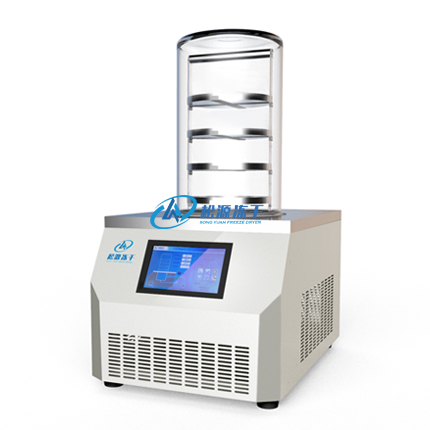

LGJ-10 standard experimental vacuum freeze dryer is widely used in medicine, pharmaceutical, biological research, chemical and food. The lyophilized materials are easy to store for a long time, and can be restored to the state before lyophilization and maintain the original biochemical characteristics after adding water. The LGJ-10 freeze dryer is suitable for laboratory use and meets the requirements of routine lyophilization in most laboratories.

Main Features

. All-in-one structure , small size, no external flange, easy to use, no leakage.

. All materials in contact with the product use inert materials to meet the requirements of the GLP.

. The cold trap andconsole are made of stainless steel, which is anti-corrosion and easy to clean.

. All stainless steel inflated /water release valveis designed and producedby our company,which is safety,anti-corrosion, no leakage.

. With sample pre-frozen function, large cold trap opening, no inner coil,and low temperature refrigerator is needless.

. Patented gas diversion technology, and strong iceholding ability.

. World- knownbrand compressors, high efficiency, long life, low noise.

. Well-known brand vacuum pump with a high pumping speed to achieve a higher ultimate vacuum.

. Vacuum pump protection function can set the cold trap temperature to protect the vacuum pump life.

. Professionally designed FD-LAB freeze-drying machine control system + SH-HPSC-I modular controller with high reliability and stability.

. Intelligent data recording system can real-time record and display the cold trap temperature curve, sample temperature curve, vacuum curve.

. Cold trap electrical heat defrosting

Technical Parameters

|

freeze drying area |

0.12㎡ |

|

material tray dia. |

Ф240mm |

|

No. of tray |

4pcs |

|

tray spacing |

70mm |

|

cold trap temperature |

≤-56℃,optional≤-80℃ |

|

cold trap dept |

140mm |

|

cold trap dia. |

Ф215mm |

|

ice collecting capacity |

3-4kg/24h |

|

pumping speed |

2L/S |

|

ultimate vacuum |

≤5Pa |

|

power |

970w |

|

weight |

41kg |

|

overall dimensions |

615×450×370mm |

|

-80℃ overall dimensions |

850×680×405mm |

|

drying chamber size |

Ф260×430mm |

|

cooling mode |

wind cooled |

|

defrosting mode |

air cooled |

|

material capacity |

1.2L(thickness 10mm) |

Optional accessories and functions

·cold trap temperature -80℃

·vacuum pump anti-returned oil device

·oil mist filter system

·imported vacuum pump

·non-standard customized

Applications

Suitable for freeze drying of conventional materials in bulk (liquid, paste, solid).

Main Features

. All-in-one structure , small size, no external flange, easy to use, no leakage.

. All materials in contact with the product use inert materials to meet the requirements of the GLP.

. The cold trap andconsole are made of stainless steel, which is anti-corrosion and easy to clean.

. All stainless steel inflated /water release valveis designed and producedby our company,which is safety,anti-corrosion, no leakage.

. With sample pre-frozen function, large cold trap opening, no inner coil,and low temperature refrigerator is needless.

. Patented gas diversion technology, and strong iceholding ability.

. World- knownbrand compressors, high efficiency, long life, low noise.

. Well-known brand vacuum pump with a high pumping speed to achieve a higher ultimate vacuum.

. Vacuum pump protection function can set the cold trap temperature to protect the vacuum pump life.

. Professionally designed FD-LAB freeze-drying machine control system + SH-HPSC-I modular controller with high reliability and stability.

. Intelligent data recording system can real-time record and display the cold trap temperature curve, sample temperature curve, vacuum curve.

Technical Parameters

|

freeze drying area |

0.12㎡ |

|

material tray dia. |

Ф240mm |

|

No. of tray |

4pcs |

|

tray spacing |

70mm |

|

cold trap temperature |

≤-56C,optional≤-80℃ |

|

cold trap dept |

140mm |

|

cold trap dia. |

Ф215mm |

|

ice collecting capacity |

3-4kg/24h |

|

pumping speed |

2L/S |

|

ultimate vacuum |

≤5pa |

|

power |

970w |

|

weight |

41kg |

|

overall dimensions |

615×450×370mm |

|

-80℃ overall dimensions |

850×680×405mm |

|

drying chamber size |

Ф260×430mm |

|

cooling mode |

wind cooled |

|

defrosting mode |

air cooled |

|

material capacity |

1.2L(thickness 10mm) |

Optional accessories and functions

·cold trap temperature -80℃

·vacuum pump anti-returned oil device

·oil mist filter system

·imported vacuum pump

·non-standard customized

Suitable for freeze-drying bulk(liquid, paste or solidity) conventional materials.

Related users (part)

Tsinghua University Peking University Huazhong Agricultural University

Beihang University, Chinese Academy of Medical Sciences, Nanjing University of Science and Technology

Beijing University of Science and Technology China Agricultural University South China University of Technology

Beijing Institute of Technology Nanjing University of Technology Xi'an University of Technology

Sichuan University Hunan University Qiqihar University

Tianjin University Lanzhou University Xiamen University

Tongji University Nanjing University Shenyang Pharmaceutical University

Zhejiang Sci-Tech University Zhongshan University Wuhan University

Zhejiang University Hunan University of Science and Technology Wuhan University of Technology

University of Science and Technology of China, Guangdong Ocean University Hubei Hong Pharmaceutical Co., Ltd.

Civil Aviation University of China Shenyang University of Technology Institute of Process Engineering, Chinese Academy of Sciences

Huazhong University of Science and Technology Beijing Orchard Research Institute Changsha Qixi New Material Technology Co., Ltd.

Beijing University of Chemical Technology Shandong Daguan Pharmaceutical Technology Co., Ltd. Dongguan City Original Ecological Biotechnology Co., Ltd.

Guizhou Institute of Biotechnology Sanming Hezhong Biotechnology Co., Ltd Harbin Children's Pharmaceutical Factory

National University of Defense Technology Changchun Hengchen Biotechnology Co., Ltd. Jinan Hengjian Pharmaceutical Technology Co., Ltd.

Institute of Chemistry, Chinese Academy of Sciences Dongguan Lujian Biotechnology Co., Ltd. Institute of Materia Medica, Chinese Academy of Medical Sciences

South China Sea Fisheries Research Institute Shanghai Institute of Materia Medica, Chinese Academy of Sciences Jiangsu Ouwei Pharmaceutical Co., Ltd.

Ministry of Agriculture Planning and Design Institute Shenzhen Jianyuan Pharmaceutical Technology Co., Ltd. Hangzhou Baicheng Pharmaceutical Technology Co., Ltd.

China Institute of Metrology Science Dongguan Sanwei Biotechnology Co., Ltd. Fujian Institute of Research on the Structure of Matter, Chinese Academy of Sciences

Liaoning Wanjia Pharmaceutical Technology Co., Ltd. Suzhou Global Chromatography Co., Ltd. China Food and Drug Testing Institute Food Institute