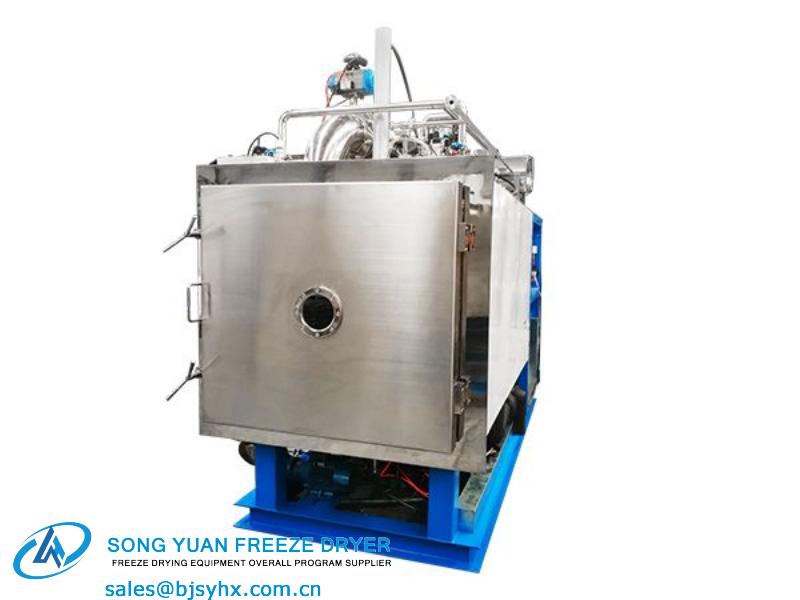

GZLYZ 5-10 Medical Freeze Dryer series are widely used in medical field, such as blood products, vaccines, biological products, and chemical medicines, especially western medicine field. This series models are used in many large-scale pharmaceutical factories. In terms of injections, drug quality can be improved and storage time can be delayed through freeze drying.

GZLYZ 5-10 Medical Freeze Dryer Main features

● The shelves are made with unique patented technology, high pressure resistance, high flatness, and good temperature uniformity.

● The cooling speed can be controlled throught The freeze-drying curve optimization control technology in the pre-frozen phase, and at the same time, the sample heating speed and the current vacuum value also can be controlled in the sublimation and analytical drying stages.

● The patented gas diversion design and control technology ,strong ice collecting capacity and high drying efficiency.

● The unique dual-channel sealing technology of the mobile + fixed dual-channel door seals sterilizes the stationary silicone rubber while steam sterilizing.

● Vacuum adjustment during drying operation to avoid foaming and blowing of special materials and improve drying efficiency.

● Industrial-grade embedded touch screen + dedicated SH-HPSC-IV modular controller, stable and reliable system, high control accuracy.

● The professionally designed LYO-CONTROL control system can save multiple sets of process . At the same time, the process can be adjusted in real time during the drying process to improve the process optimization rate.

● Flexible manual + automatic control mode, the manual for groping process, and the automatic for batch production.

● The powerful LYO-MEGA host computer control system can record and save the operating data, curves and alarm records for ten years to improve the traceability of products; at the same time, it is convenient for observation, operation and fault diagnosis.

● User grades and passwords can be set, and operations can be decentralized to meet GMP-related requirements.

● The non-stardarded can be customized as requested.

| models parameters |

unit | GZLZ-1 | GZLZ-2 | GZLZ-3 | GZLZ-5 | GZLZ-10 |

| freeze drying area | m2 | 1.15 | 2.16 | 3.24 | 5.2 | 10.5 |

| shipping weight (thickness 10mm) |

L | 10 | 20 | 30 | 50 | 100 |

| shelf numbers | layer | 4+1 | 4+1 | 6+1 | 7+1 | 7+1 |

| shelf dimensions | mm | 600*480 | 600*900 | 600*900 | 750*1000 | 990*1520 |

| shelf spacing | mm | 80 | 80 | 80 | 80 | 80 |

| temp. range | ℃ | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 |

| ice collecting capacity | kg/B | ≥20 | ≥40 | ≥60 | ≥100 | ≥300 |

| cold trap temp. | ℃ | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 |

| cooling mode | - | water cooled | water cooled | water cooled | water cooled | water cooled |

| defrosting mode | - | water soaked | water soaked | water soaked | water soaked | water soaked |

| ultimate vacuum | pa | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| power | kw | 18 | 21 | 24 | 25 | 58 |

| dimensions (L*W*H) |

m | 2500*1100*2000 | 2500*1300*2000 | 2800*1200*2500 | 4000*1500*2500 | 6700*1800*3500 |

| vials Φ22 | pcs | 2460 | 4608 | 6912 | 11648 | 22932 |

| vials Φ16 | pcs | 4788 | 8960 | 13440 | 22540 | 42966 |

| weight | kg | 1500 | 2600 | 2800 | 5000 | 7000 |

| steaming water consumption | kg/h | 60 | 80 | 100 | 130 | 200 |

| inpouring water volume | l/min | 60 | 75 | 90 | 120 | 160 |

GZLYZ 5-10 Medical Freeze Dryer Applications

It is used for the pharmaceutical factories

This model is not only suitable for the freeze drying of bulk (liquid, pasty, solid) conventional materials, but also suitable for the drying of the vials materials. When the materials are ready for freeze-drying, they are put into in the vial, then begin freeze drying before the vial's lid unsealed. The capping device compacts the vials' lids after freeze drying to prevent secondary pollution, re-adsorb water, and facilitate long-term storage.

GZLYZ 5-10 Medical Freeze Dryer Main features

● The shelves are made with unique patented technology, high pressure resistance, high flatness, and good temperature uniformity.

● The cooling speed can be controlled throught The freeze-drying curve optimization control technology in the pre-frozen phase, and at the same time, the sample heating speed and the current vacuum value also can be controlled in the sublimation and analytical drying stages.

● The patented gas diversion design and control technology ,strong ice collecting capacity and high drying efficiency.

● The unique dual-channel sealing technology of the mobile + fixed dual-channel door seals sterilizes the stationary silicone rubber while steam sterilizing.

● Vacuum adjustment during drying operation to avoid foaming and blowing of special materials and improve drying efficiency.

● Industrial-grade embedded touch screen + dedicated SH-HPSC-IV modular controller, stable and reliable system, high control accuracy.

● The professionally designed LYO-CONTROL control system can save multiple sets of process . At the same time, the process can be adjusted in real time during the drying process to improve the process optimization rate.

● Flexible manual + automatic control mode, the manual for groping process, and the automatic for batch production.

● The powerful LYO-MEGA host computer control system can record and save the operating data, curves and alarm records for ten years to improve the traceability of products; at the same time, it is convenient for observation, operation and fault diagnosis.

● User grades and passwords can be set, and operations can be decentralized to meet GMP-related requirements.

● The non-stardarded can be customized as requested.

| models parameters |

unit | GZLZ-1 | GZLZ-2 | GZLZ-3 | GZLZ-5 | GZLZ-10 |

| freeze drying area | m2 | 1.15 | 2.16 | 3.24 | 5.2 | 10.5 |

| shipping weight (thickness 10mm) |

L | 10 | 20 | 30 | 50 | 100 |

| shelf numbers | layer | 4+1 | 4+1 | 6+1 | 7+1 | 7+1 |

| shelf dimensions | mm | 600*480 | 600*900 | 600*900 | 750*1000 | 990*1520 |

| shelf spacing | mm | 80 | 80 | 80 | 80 | 80 |

| temp. range | ℃ | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 |

| ice collecting capacity | kg/B | ≥20 | ≥40 | ≥60 | ≥100 | ≥300 |

| cold trap temp. | ℃ | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 |

| cooling mode | - | water cooled | water cooled | water cooled | water cooled | water cooled |

| defrosting mode | - | water soaked | water soaked | water soaked | water soaked | water soaked |

| ultimate vacuum | pa | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| power | kw | 18 | 21 | 24 | 25 | 58 |

| dimensions (L*W*H) |

m | 2500*1100*2000 | 2500*1300*2000 | 2800*1200*2500 | 4000*1500*2500 | 6700*1800*3500 |

| vials Φ22 | pcs | 2460 | 4608 | 6912 | 11648 | 22932 |

| vials Φ16 | pcs | 4788 | 8960 | 13440 | 22540 | 42966 |

| weight | kg | 1500 | 2600 | 2800 | 5000 | 7000 |

| steaming water consumption | kg/h | 60 | 80 | 100 | 130 | 200 |

| inpouring water volume | l/min | 60 | 75 | 90 | 120 | 160 |

It is used for the pharmaceutical factories

This model is not only suitable for the freeze drying of bulk (liquid, pasty, solid) conventional materials, but also suitable for the drying of the vials materials. When the materials are ready for freeze-drying, they are put into in the vial, then begin freeze drying before the vial's lid unsealed. The capping device compacts the vials' lids after freeze drying to prevent secondary pollution, re-adsorb water, and facilitate long-term storage.

Related users (part)

Tonghua Jitong Pharmaceutical Co., Ltd. Yangzijiang Pharmaceutical Yunnan Qidan Pharmaceutical Co., Ltd.

Hunan Sailong Pharmaceutical Co., Ltd Yunnan Baiyao Pharmaceutical Co., Ltd. Qilu Pharmaceutical Co., Ltd.

Changzhou Jinyuan Pharmaceutical Manufacturing Co., Ltd. Quanzhou Southeast Pharmaceutical Co., Ltd. Shaanxi Junbisha Pharmaceutical Co., Ltd.

Changzhou Fangyuan Pharmaceutical Co., Ltd. Yinfeng Cryogenic Medicine Technology Co., Ltd. Shenzhen Guoyuan Chinese Medicine Co., Ltd.

Beijing Aviation Material Research Institute Jilin Tian Peptide Biotechnology Co., Ltd. Beijing Lepu Medical Devices Co., Ltd.

Tonghua Baiquan Health Food Co., Ltd. Xinjiang Zhonghe Co., Ltd. Shandong Cysecs Pharmaceutical Co., Ltd.

Yantai Huasheng Biomedical Technology Co., Ltd. Xinjiang Wangyuan Biotechnology Group Taizhou Zecheng Biotechnology Co., Ltd.

Chongqing Dingrun Medical Devices Co., Ltd. Nantong Lance Biotechnology Co., Ltd. Tsinghua University

Kang Long Hua Cheng (Beijing) New Drug Technology Co., Ltd Hunan Zhong Sheng Quan Peptide Bio Technology Co., Ltd. Bao Tai Long New Material Co., Ltd.

Fast Wake Biotech (Beijing) Co., Ltd. Kunming Silcom Biotechnology Co., Ltd. Zhongshi Bio (RongCheng) Technology Co., Ltd.

Beijing Oriental Anjie Technology Co., Ltd. Guangdong Occupational Disease Prevention and Treatment Center Harbin Hertz New Material Technology Co., Ltd.

Dacheng Wanda (Tianjin) Co., Ltd. Zhuhai Golden Peptide Biotechnology Co., Ltd. Shenzhen Huabo Biotechnology Development Co., Ltd.

Beijing Red Sun Pharmaceutical Co., Ltd. Guangzhou Xin Man Cosmetics Co., Ltd. Beijing Wantai Bio-Pharmaceutical Co., Ltd.

Dongguan Biotechnology Research Institute Beijing Dongxin Lipo Technology Co., Ltd. Beijing Xiehe Lock Biotechnology Co., Ltd.

Qingdao Mingyue Seaweed Group Co., Ltd. Gansu Province Guazhou Shengtai Bio-Technology Co., Ltd. Beijing Dongfang Norbow Technology Development Co., Ltd.

Hebi Xingwang Biological Co., Ltd. Xiangshan Zhenyu Food Machinery Manufacturing Co., Ltd. Yangpu Medical (Hunan) Co., Ltd.

Yunnan Tin Group Jiangxi Materia Medica Tiangong Technology Co., Ltd. Han Chenshi (Shenyang) Biological Medicine Development Co., Ltd.

Qinghai Ruiyuan Pharmaceutical Co., Ltd. Chuxiong Century Huabao Biological Industry Development Co., Ltd. Chengdu chuanling Herbal Pieces Selection Co., Ltd.

Shaanxi Institute of Microbiology Hong Kong Youcheng International Co., Ltd. Zhejiang Jinshi Biotechnology Co., Ltd.

Jinan Sanfeng Biological Engineering Co., Ltd. Beijing Luqiao Biotechnology Co., Ltd. Qinghai Ameta Shangpincao Biological Technology Co., Ltd.